-

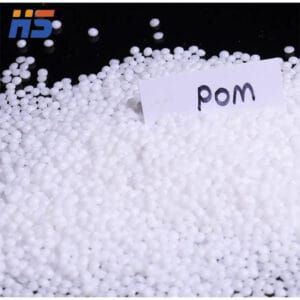

POM Granules is a very hard self-lubricating plastic and white, although it is usually colored with the most varied shades.

It is a semi crystalline polymer with a low coefficient of friction, resistant to heat and abrasion, with low water absorption and optimal electrical properties

-

POM resin also called acetyl or acetyl resin, is a very hard self-lubricating plastic and white, although it is usually colored with the most varied shades.

It is a semi crystalline polymer with a low coefficient of friction, resistant to heat and abrasion, with low water absorption and optimal electrical properties

-

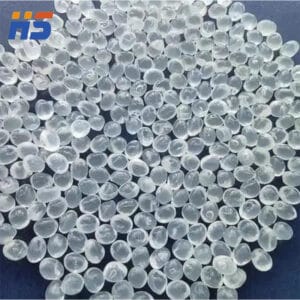

POM Plastic Pellets also called acetyl or acetyl resin, is a very hard self-lubricating plastic and white, although it is usually colored with the most varied shades.

It is a semi crystalline polymer with a low coefficient of friction, resistant to heat and abrasion, with low water absorption and optimal electrical properties

-

POM resin also called acetyl or acetyl resin, is a very hard self-lubricating plastic and white, although it is usually colored with the most varied shades.

It is a semi crystalline polymer with a low coefficient of friction, resistant to heat and abrasion, with low water absorption and optimal electrical properties

-

Acetal Resin is a very hard self-lubricating plastic and white, although it is usually colored with the most varied shades.

It is a semi crystalline polymer with a low coefficient of friction, resistant to heat and abrasion, with low water absorption and optimal electrical properties