Showing 19–23 of 23 results

-

ABS acrylonitrile butadiene styrene polymer, abbreviated as ABS, is a ternary copolymer composed of acrylonitrile, butadiene, and styrene. ABS has excellent comprehensive physical and mechanical properties, as well as excellent low-temperature impact resistance. Dimensional stability. Good electrical performance, wear resistance, chemical resistance, dyeing resistance, finished product processing and mechanical processing.ABS resin is resistant to water, inorganic salts, alkalis, and acids, and is insoluble in most alcohol and hydrocarbon solvents. Low thermal deformation temperature, flammable, and poor weather resistance.

-

Product Details

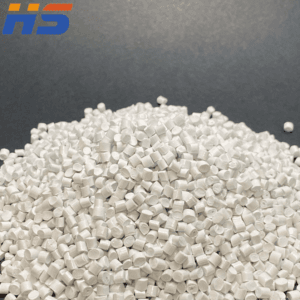

color: Natural

Form: Granules Plastic Pellets

Flexural Strength: 62 Mpa

Flexural Modulus: 2060 Mpa

Elongation at Break: 20 percent

Density: 1.08 G/cm3

Tensile Strength: 40 MPa

Izod Impact, Notched: 120 J/M

-

Our recycling process of ABS Plastic

- For initiating and getting the recycled ABS plastic, we begin from collecting tons of ABS plastic. The recycling takes place for bulk pellets in one go, to reduce the commercial and environmental expenses.

- The first step is to banish all the possible contaminants from the ABS Plastic Material, which belong to the non-ABS plastic material category. There is a need to collect all the waste away from the ABS plastic to process it further.

- We store the processed material in stillages or boxes, where we use the haulage partners. The entire recycling facility takes place with the ABS Plastic Material.

- Every ABS Recycled Pellet should suit to the environment. Therefore, to serve the requirement, we prefer the quality check and inspect that closely. It helps us to balance and maintain environmental reporting.

- As a final step of getting the ABS Recycled Pellet, the entire material passes through the granulator. It helps us to create multiple pellets of ABS plastics.

Properties of ABS plastic available with us

You can rely on us as we provide the best ABS plastic material, engrossed with multiple properties:

- The typical composition of recycled ABS Plastic includes 50 percent of styrene and the rest half is balanced between the butadiene and acrylonitrile.

- To get tougher ABS plastic, the proportion of butadiene rubber should be increased.

- The inclusion of Styrene serves the ABS plastic with a shinier and impervious surface.

- ABS plastic has high impact resistance and resilience comes from the Butadiene inclusion in the same.

- The ABS recycled plastic is easily soluble ketones, esters, and ethylene dichloride.

To know more about recycled ABS plastic material or to avail our services, feel free to contact us. Our recyclable material will help to maintain a greener environment around you.

-

-

Application: OA Auto Part

Form: Granules Plastic Pellets

Flexural Strength: 62 Mpa

Flexural Modulus: 2060 Mpa

Elongation at Break: 20 percent

Density: 1.08 G/cm3

Tensile Strength: 40 MPa

Izod Impact, Notched: 120 J/M