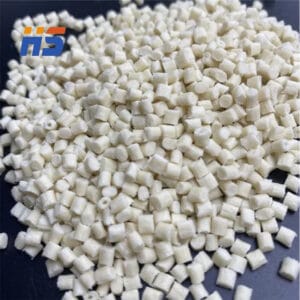

Expandable Polystyrene EPS Foam Resin Beads Granules

Expandable Polystyrene

Color: White

Shape: Granule

Application: Stuffing, household items, toys, Packaging, Building

Feature: Flame retardant grade, General grade, Light grade

Showing 46–54 of 174 results

Expandable Polystyrene

Color: White

Shape: Granule

Application: Stuffing, household items, toys, Packaging, Building

Feature: Flame retardant grade, General grade, Light grade

Flame Retardant ABS

Color: Black

Form: Granules Plastic Pellets

Flexural Strength: 62 Mpa

Flexural Modulus: 2060 Mpa

Elongation at Break: 20 percent

Density: 1.08 G/cm3

Tensile Strength: 40 MPa

Izod Impact, Notched: 120 J/M

PBT Material Features:

Have good toughness Have fatigue resistance, heat resistance, weather resistance

Have electric property and low water absorption

Improve heat resistance, modulus, dimension stability and flammability

Main Applications

Mainly used in the automotive, electronic and electrical, industrial machinery, and polymer alloy blending industry. In the electronic and electrical industry, it can be used to make deflection coils for televisions, CRT and potentiometer brackets, sound output transformer frames, adapter frames, as well as switch connectors, fans, refrigerators, washing machine motor end covers, and shaft sleevesProduct Parameters

| item | value |

| Place of Origin | China |

| Brand | Huashang |

| Model Number | PBT |

| Product name | PBT |

| Application | Car Wheel ,Corrugated pipe etc |

| Grade | Injection/extrusion |

| Type | Virgin and Recycled |

| Color | White,Black,Natural Color |

| Package | 25 KG Per Bag |

| Origin | ShanDong,China |

or polyetherimide, is a high-performance amorphous thermoplastic known for its excellent mechanical, thermal, and electrical properties. It’s a strong, rigid, and dimensionally stable material, making it suitable for demanding applications in various industries. PEI is often used as an alternative to PEEK in some applications due to its lower cost, but it offers a narrower temperature range.

PPO Resin Polyphenylene Oxide (PPO) is a lightweight resin that’s commonly used and mixed with other resins to facilitate manufacturing processes. It resists heat very well, and as a result, can’t easily be melted down and used in different injection molds or recycled for other uses.

PVC Material is a material consisting of PVC resin, plasticizer, minerals and required additives that is produced during the mixing process by compounding machines. PVC granules have a wide range of properties and are produced in the form of soft and hard granules.

Soft PVC Plastic Granules:

The hardness range of soft granules is usually between 40 and 100 (Shore A). In order to reduce the hardness, certain amount of some kinds of plasticizers are used in the production of soft PVC granules.

A branch of soft PVC granules are TPE granules, which are combined with a substance called NBR to increase the elasticity of the granules. Soft PVC granules are widely used in wire and cable industries, automobiles, injection, shoes, doors and windows, etc.

Hard PVC Plastic Granules (UPVC):

Due to the insignificant use of plasticizers in this type of granules, they are called hard PVC or UPVC granules. The hardness range of UPVC granules is between 40 and 90 (Shore D). These granules are usually used to produce pipe fittings, door and window profiles, ducts, shutters, etc.

PlasticKar Company, using equipped and up-to-date machines, produces and offers a variety of soft and hard PVC compounds for various applications in a wide range of industries as follows:

PVC Pellets is a material consisting of PVC resin, plasticizer, minerals and required additives that is produced during the mixing process by compounding machines. PVC granules have a wide range of properties and are produced in the form of soft and hard granules.

Soft PVC Plastic Granules:

The hardness range of soft granules is usually between 40 and 100 (Shore A). In order to reduce the hardness, certain amount of some kinds of plasticizers are used in the production of soft PVC granules.

A branch of soft PVC granules are TPE granules, which are combined with a substance called NBR to increase the elasticity of the granules. Soft PVC granules are widely used in wire and cable industries, automobiles, injection, shoes, doors and windows, etc.

Hard PVC Plastic Granules (UPVC):

Due to the insignificant use of plasticizers in this type of granules, they are called hard PVC or UPVC granules. The hardness range of UPVC granules is between 40 and 90 (Shore D). These granules are usually used to produce pipe fittings, door and window profiles, ducts, shutters, etc.

PlasticKar Company, using equipped and up-to-date machines, produces and offers a variety of soft and hard PVC compounds for various applications in a wide range of industries as follows:

Expandable Polystyrene

Color: White

Shape: Granule

Application: Stuffing, household items, toys, Packaging, Building

Feature: Flame retardant grade, General grade, Light grade

PA polyamide has excellent mechanical properties, electrical properties, wear resistance, chemical resistance, and lubricity, but it also has outstanding shortcomings, such as high water absorption, resulting in poor dimensional stability, and is also used as an engineering material. The mechanical properties still need to be further improved.

In practical applications, PA6 PA66 is the most used. The focus here is on the modification of PA6 PA66. Mainly modified from the following aspects

1 reduce the water absorption of PA to improve the dimensional stability of the product;

2 Improve the flame retardancy of PA to meet the requirements of electronics, electrical, communication and other fields;

3 Improve the mechanical mildness of the PA to achieve the strength of the metal material to meet the structural material requirements;

4 Improve the low temperature resistance of PA and enhance its ability to resist environmental stress cracking

5 Improve the wear resistance of PA to adapt to the occasions with high wear resistance;

6 Improve the antistatic property of PA to meet the requirements of mining machinery applications;

7 Improve the heat resistance of PA to adapt to the field of high temperature conditions such as automobile engines.