Showing 136–144 of 174 results

-

-

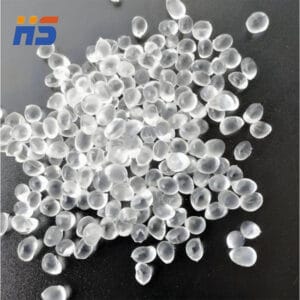

PVC Granulesis a material consisting of PVC resin, plasticizer, minerals and required additives that is produced during the mixing process by compounding machines. PVC granules have a wide range of properties and are produced in the form of soft and hard granules.

Soft PVC Plastic Granules:

The hardness range of soft granules is usually between 40 and 100 (Shore A). In order to reduce the hardness, certain amount of some kinds of plasticizers are used in the production of soft PVC granules.

A branch of soft PVC granules are TPE granules, which are combined with a substance called NBR to increase the elasticity of the granules. Soft PVC granules are widely used in wire and cable industries, automobiles, injection, shoes, doors and windows, etc.

Hard PVC Plastic Granules (UPVC):

Due to the insignificant use of plasticizers in this type of granules, they are called hard PVC or UPVC granules. The hardness range of UPVC granules is between 40 and 90 (Shore D). These granules are usually used to produce pipe fittings, door and window profiles, ducts, shutters, etc.

PlasticKar Company, using equipped and up-to-date machines, produces and offers a variety of soft and hard PVC compounds for various applications in a wide range of industries as follows:

- Wire, cable and electrical industries

- Building industry

- Shoe industry

- Hose industry

- Other granules

-

The properties of S-198AL Pellets (Poliuretano termoplastico) S-198AL :

- Its excellent abrasion resistance, flexibility, and durability make it suitable for shoe soles

- Its ability to provide impact resistance and flexibility, while maintaining a soft and rubbery feel, make it a popular choice for consumer goods

- Its resistance to chemicals, oils, and abrasion makes it ideal for creating durable and reliable industrial components.

- Its flexibility and resistance to environmental factors make it suitable for electronic components

| Physical Properties | Test Standard | Unit | Typical Value* |

| Density | ASTM D792 | g/cm3 | 1.23±0.02 |

| Shore Hardness | ASTM D2240 | Shore A Shore D | 98±2 A |

| Tensile Strength | ASTM D412 | Kgf/cm2 | 350 |

| Elongation at Break | ASTM D412 | % | 400 |

| 100% Tensile Strength | ASTM D412 | Kgf/cm2 | 120 |

| 300% Tensile Strength | ASTM D412 | Kgf/cm2 | 150 |

| Tear Strength | ASTM D624 | Kgf/cm | 130 |

| Molding Conditions |

| Drying | Drying Temperature | 100°C |

| Drying Time | 2-4hrs |

| Processing | Processing Temperature | 190-215°C |

| Processing Mold | Injection Molding |

-

POE Elastomer derived from Polyolefin Elastomer, are versatile plastic granules used in various industries due to their flexibility, weather resistance, and impact resistance. They are primarily used for toughening PP, PE, and PA in the automotive industry, for insulation and sheathing in wire and cable, and also for industrial products like hoses and conveyor belts. Furthermore, they find applications in medical devices, household appliances, sporting goods, and packaging films.

-

LDPE Granules

Low-Density Polyethylene pellets

Application: Blown film

Melt Flow Index: 1-2

Origin: Post industrial material,

Packaging: big-bags.

Recycled LDPE (rLDPE) Pellets are made from post-consumer low-density polyethylene waste, such as plastic bags, wraps, and packaging. These eco-friendly pellets offer a sustainable alternative to virgin LDPE, providing excellent flexibility, strength, and performance for a variety of applications.

Ideal for use in packaging, film production, and consumer goods, our rLDPE pellets help businesses reduce their environmental impact while maintaining product quality. By choosing recycled LDPE, you contribute to a circular economy and promote responsible manufacturing practices.

Key Features:

- Made from 100% recycled LDPE

- Flexible, durable, and versatile for various applications

- Eco-friendly and cost-effective alternative to virgin LDPE

- Supports waste reduction and sustainable production

Choose our Recycled LDPE Pellets for a greener, more sustainable future while upholding the quality and performance of your products.

-

TPR Pellets or Thermoplastic Rubber, is a material that combines the properties of both rubber and plastic. It is a versatile material that can be easily processed using techniques like injection molding. TPR is known for its flexibility, durability, and resistance to chemicals and weathering

Flexibility and Elasticity:

TPR exhibits rubber-like flexibility and elasticity, making it suitable for applications requiring a material that can bend and deform without breaking.

Durability and Strength:

It offers good tensile strength, tear resistance, and resistance to fatigue, allowing it to withstand mechanical stress and long-term use.

Chemical and Weather Resistance:

TPR is resistant to many chemicals and weathering, making it suitable for outdoor and industrial applications.

Processability:

Being a thermoplastic, TPR can be melted and reshaped multiple times, allowing for efficient manufacturing processes like injection molding and extrusion.

Recyclability:

TPR can be recycled, making it a more environmentally friendly option compared to some other materials.

-

Thermoplastic Rubber, is a material that combines the properties of both rubber and plastic. It is a versatile material that can be easily processed using techniques like injection molding. TPR is known for its flexibility, durability, and resistance to chemicals and weathering

Flexibility and Elasticity:

TPR exhibits rubber-like flexibility and elasticity, making it suitable for applications requiring a material that can bend and deform without breaking.

Durability and Strength:

It offers good tensile strength, tear resistance, and resistance to fatigue, allowing it to withstand mechanical stress and long-term use.

Chemical and Weather Resistance:

TPR is resistant to many chemicals and weathering, making it suitable for outdoor and industrial applications.

Processability:

Being a thermoplastic, TPR can be melted and reshaped multiple times, allowing for efficient manufacturing processes like injection molding and extrusion.

Recyclability:

TPR can be recycled, making it a more environmentally friendly option compared to some other materials.

-

TPEE Elastomer Granules :Thermoplastic polyester elastomer (TPE-E or TPEE), also known as thermoplastic Copolyester, are a class of multiblock copolymers or a physical mix of polymers (usually a plastic and a rubber) which consist of materials with both thermoplastic and elastomeric properties.

Thermoplastic elastomers show both advantages typical of rubbery and plastic materials. The principal difference between thermoset elastomers and thermoplastic elastomers is the type of crosslinking bond in their structures. In fact, crosslinking is a critical structural factor which contributes to impart high elastic properties. The crosslink in thermoset polymers is a covalent bond created during the vulcanization process.

On the other hand the crosslink in thermoplastic elastomer polymers is a weaker dipole or hydrogen bond or takes place in one of the phases of the material.

-

TPEE Material :Thermoplastic polyester elastomer (TPE-E or TPEE), also known as thermoplastic Copolyester, are a class of multiblock copolymers or a physical mix of polymers (usually a plastic and a rubber) which consist of materials with both thermoplastic and elastomeric properties.

Thermoplastic elastomers show both advantages typical of rubbery and plastic materials. The principal difference between thermoset elastomers and thermoplastic elastomers is the type of crosslinking bond in their structures. In fact, crosslinking is a critical structural factor which contributes to impart high elastic properties. The crosslink in thermoset polymers is a covalent bond created during the vulcanization process.

On the other hand the crosslink in thermoplastic elastomer polymers is a weaker dipole or hydrogen bond or takes place in one of the phases of the material.