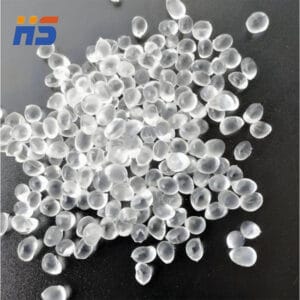

TPR Material for Flexible Over-Molding Applications

TPR Material, or Thermoplastic Rubber, is a material that combines the properties of both rubber and plastic. It is a versatile material that can be easily processed using techniques like injection molding. TPR is known for its flexibility, duurzaamheid, and resistance to chemicals and weathering

- Flexibility and Elasticity:TPR exhibits rubber-like flexibility and elasticity, making it suitable for applications requiring a material that can bend and deform without breaking.

- Durability and Strength:It offers good tensile strength, tear resistance, and resistance to fatigue, allowing it to withstand mechanical stress and long-term use.

- Chemical and Weather Resistance:TPR is resistant to many chemicals and weathering, making it suitable for outdoor and industrial applications.

- Processability:Being a thermoplastic, TPR can be melted and reshaped multiple times, allowing for efficient manufacturing processes like injection molding and extrusion.

- Recyclability:TPR can be recycled, making it a more environmentally friendly option compared to some other materials.