Vergeleken met nylon, PBT heeft 230% hogere slagsterkte. Het heeft ook een uitstekende hydrolysebestendigheid. Het behoudt een hoge treksterkte en slagsterkte onder natte omstandigheden, en heeft een hoge rek.

PK hoge warmtevervormingstemperatuur: HDT bedraagt 200℃, kan lange tijd worden gebruikt in een omgeving met hoge temperaturen

PK heeft een uitstekende chemische resistentie: chemische resistentie komt op de tweede plaats na PPS. Water- en waterdampstabiliteit

PK heeft hoge barrière-eigenschappen: koolwaterstoffen. Geslaagd voor de permeabiliteitstest van loodvrije benzine @93℃*15 dagen, beter dan teflon, en de gasbarrière is gelijkwaardig aan EVOH

PK heeft goede wrijvingsprestaties: de slijtvastheid is 14 keer die van POM en het heeft een uitstekend laag geluidsniveau

PK heeft een hoge productie-efficiëntie, en polyketon met hoge kristalliniteit helpt de vormcyclus te verkorten

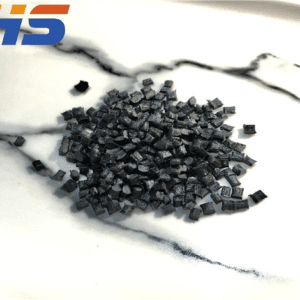

PK-hoofdtoepassingen

| veld | Toepassingsvoorbeelden |

|---|

| Automotive-toepassingen | Doppen voor brandstoftanks, accessoires voor brandstofleidingen, wielnaafafdekkingen, koelwaterkamers, auto-connectoren |

| werktuigbouwkunde | Versnellingen, lagers, katrollen, watermeterbehuizingen, ketting platen |

| Elektronische apparaten en consumentenproducten | Kabeldozen, stroomonderbrekers, onderdelen van vloerschrobmachines |

Veel gebruikt in machines, instrumenten, auto-onderdelen, elektrische en elektronische apparatuur, spoorwegen, huishoudelijke apparaten, communicatie, textielmachines, sport- en vrijetijdsproducten, oliepijpleidingen, brandstoftanks en enkele precisietechnische producten.