Showing 91–99 van 174 resultaat

-

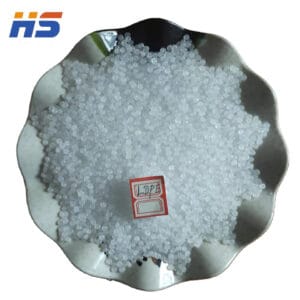

LDPE Plastic Granules, Grade A.

Low-Density Polyethylene pellets

Sollicitatie: Blown film

Melt Flow Index: 1-2

Oorsprong: Post industrial material,

Packaging: big-bags.

Recycled LDPE (rLDPE) Pellets are made from post-consumer low-density polyethylene waste, such as plastic bags, wraps, and packaging. These eco-friendly pellets offer a sustainable alternative to virgin LDPE, providing excellent flexibility, strength, and performance for a variety of applications.

Ideal for use in packaging, film production, and consumer goods, our rLDPE pellets help businesses reduce their environmental impact while maintaining product quality. By choosing recycled LDPE, you contribute to a circular economy and promote responsible manufacturing practices.

Belangrijke functies:

- Made from 100% recycled LDPE

- Flexible, duurzaam, and versatile for various applications

- Eco-friendly and cost-effective alternative to virgin LDPE

- Supports waste reduction and sustainable production

Choose our Recycled LDPE Pellets for a greener, more sustainable future while upholding the quality and performance of your products.

-

LDPE Plastic Granules, Grade A.

Low-Density Polyethylene pellets

Sollicitatie: Blown film

Melt Flow Index: 1-2

Oorsprong: Post industrial material,

Packaging: big-bags.

Recycled LDPE (rLDPE) Pellets are made from post-consumer low-density polyethylene waste, such as plastic bags, wraps, and packaging. These eco-friendly pellets offer a sustainable alternative to virgin LDPE, providing excellent flexibility, strength, and performance for a variety of applications.

Ideal for use in packaging, film production, and consumer goods, our rLDPE pellets help businesses reduce their environmental impact while maintaining product quality. By choosing recycled LDPE, you contribute to a circular economy and promote responsible manufacturing practices.

Belangrijke functies:

- Made from 100% recycled LDPE

- Flexible, duurzaam, and versatile for various applications

- Eco-friendly and cost-effective alternative to virgin LDPE

- Supports waste reduction and sustainable production

Choose our Recycled LDPE Pellets for a greener, more sustainable future while upholding the quality and performance of your products.

-

Polyethylene, Grade A.

Low-Density Polyethylene pellets

Sollicitatie: Blown film

Melt Flow Index: 1-2

Oorsprong: Post industrial material,

Packaging: big-bags.

Recycled LDPE (rLDPE) Pellets are made from post-consumer low-density polyethylene waste, such as plastic bags, wraps, and packaging. These eco-friendly pellets offer a sustainable alternative to virgin LDPE, providing excellent flexibility, strength, and performance for a variety of applications.

Ideal for use in packaging, film production, and consumer goods, our rLDPE pellets help businesses reduce their environmental impact while maintaining product quality. By choosing recycled LDPE, you contribute to a circular economy and promote responsible manufacturing practices.

Belangrijke functies:

- Made from 100% recycled LDPE

- Flexible, duurzaam, and versatile for various applications

- Eco-friendly and cost-effective alternative to virgin LDPE

- Supports waste reduction and sustainable production

Choose our Recycled LDPE Pellets for a greener, more sustainable future while upholding the quality and performance of your products.

-

Poe Poe -granules, afgeleid van polyolefine -elastomeer, zijn veelzijdige plastic korrels die in verschillende industrieën worden gebruikt vanwege hun flexibiliteit, weerweerstand, en impactweerstand. Ze worden voornamelijk gebruikt voor Toestaan PP, Pe, en PA in de auto -industrie, voor isolatie en het in draad en kabel, en ook voor industriële producten zoals slangen en transportbanden. Verder, Ze vinden aanvragen op medische hulpmiddelen, huishoudelijke apparaten, sportgoederen, en verpakkingsfilms.

-

Abrylonitrile butadieen styreen polymeer, afgekort als ABS, is een ternair copolymeer bestaande uit acrylonitril, butadieen, en styreen. ABS heeft uitstekende uitgebreide fysieke en mechanische eigenschappen, evenals uitstekende impactweerstand op lage temperatuur. Dimensionale stabiliteit. Goede elektrische prestaties, Draag weerstand, chemische weerstand, Verven weerstand, Bewerking van eindproduct en mechanische verwerking. ABS Hars is bestand tegen water, anorganische zouten, alkalis, en zuren, en is onoplosbaar in de meeste oplosmiddelen voor alcohol- en koolwaterstof. Lage thermische vervormingstemperatuur, ontvlambaar, en slecht weerweerstand.

-

Productdetails

color: Natural

Formulier: Korrels plastic pellets

Buigsterkte: 62 MPA

Buigmodulus: 2060 MPA

Rek bij pauze: 20 percentage

Dikte: 1.08 G / cm3

Treksterkte: 40 MPA

Izod impact, Ingepakt: 120 J/M

-

ppo-resin Polyphenylene Oxide (PPO) is a lightweight resin that’s commonly used and mixed with other resins to facilitate manufacturing processes. It resists heat very well, and as a result, can’t easily be melted down and used in different injection molds or recycled for other uses.

-

Laminated Plastic Film is a necessity for contractors, DIYers that are remodeling their home, or anyone needing a tough En duurzaam plastic sheeting for a project. Shop our extensive selection and get the best prices and fast shipping.

-

EVA-KORRELS

Vorm: Korrels

Cijfer: Vormen, extrusie kwaliteit, spuitgietkwaliteit

Functie: Hoge stroom, Hoogglans, Chemische weerstand