Showing 127–135 de 174 résultats

-

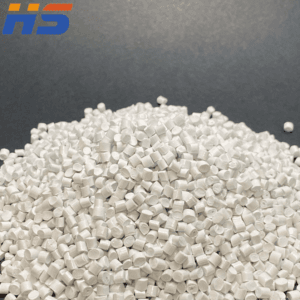

PP Pellets consist of tiny, solid particles derived from polypropylene. PP granules is a versatile thermoplastic polymer. They are renowned for their outstanding physical and chemical attributes. Their attributes include high chemical resistance, durability, and low melting point. Additionally, these granules have extensive applications across diverse industries. They serve as essential raw materials for manufacturing plastic items. They are extensively used in processes like injection moulding, extrusion, and blow moulding.

-

PPO Plastic ppo-resin Polyphenylene Oxide (PPO) est a lightweight resin that’s commonly used and mixed with other resins to facilitate manufacturing processes. It resists heat very well, and as a result, can’t easily be melted down and used in different injection molds or recycled for other uses.

-

High-temperature PPO blends for car dashboards, pump housings, and electrical enclosures. Applications: Electric vehicle battery casings, dishwasher components, and HVAC systems. Caractéristiques clés: HDT 170-190°C, EMI shielding capability. Certifications: Automotive EMC Compliance, Ul 94 V0.

-

PPS Plastic Pellets

Polyphenylene sulfide, commonly referred to as PPS, is a semi-crystalline thermoplastic with a polymeric structure that gives it a remarkable degree of chemical resistance. In fact, there are no known solvents for this high-performance thermoplastic below 392°F (200° C). Its other notable attributes are its inherent flame resistance, electrical properties and its high mechanical strength. Most commercial grades of PPS achieve a UL 94 V-0 flammability rating without flame-retardant additives.

While the unmodified PPS polymer exhibits good all-around performance, the addition of fiber-reinforcement significantly boosts its toughness, structural and thermal properties. A two-fold increase in heat deflection temperature and more than triple the flexural modulus are the main reasons for the far greater usage of 40% glass fiber-reinforced PPS over unfilled grades for load bearing molded and machined parts exposed to higher thermal conditions.

-

Granules de résine PPS

Polyphenylene sulfide, commonly referred to as PPS, is a semi-crystalline thermoplastic with a polymeric structure that gives it a remarkable degree of chemical resistance. In fact, there are no known solvents for this high-performance thermoplastic below 392°F (200° C). Its other notable attributes are its inherent flame resistance, electrical properties and its high mechanical strength. Most commercial grades of PPS achieve a UL 94 V-0 flammability rating without flame-retardant additives.

While the unmodified PPS polymer exhibits good all-around performance, the addition of fiber-reinforcement significantly boosts its toughness, structural and thermal properties. A two-fold increase in heat deflection temperature and more than triple the flexural modulus are the main reasons for the far greater usage of 40% glass fiber-reinforced PPS over unfilled grades for load bearing molded and machined parts exposed to higher thermal conditions.

-

PVC Plastic Granules is a material consisting of PVC resin, plasticizer, minerals and required additives that is produced during the mixing process by compounding machines. PVC granules have a wide range of properties and are produced in the form of soft and hard granules.

Soft PVC Plastic Granules:

The hardness range of soft granules is usually between 40 et 100 (Rive A). In order to reduce the hardness, certain amount of some kinds of plasticizers are used in the production of soft PVC granules.

A branch of soft PVC granules are TPE granules, which are combined with a substance called NBR to increase the elasticity of the granules. Soft PVC granules are widely used in wire and cable industries, automobiles, injection, shoes, doors and windows, etc..

Hard PVC Plastic Granules (UPVC):

Due to the insignificant use of plasticizers in this type of granules, they are called hard PVC or UPVC granules. The hardness range of UPVC granules is between 40 et 90 (Rive D). These granules are usually used to produce pipe fittings, door and window profiles, ducts, shutters, etc..

PlasticKar Company, using equipped and up-to-date machines, produces and offers a variety of soft and hard PVC compounds for various applications in a wide range of industries as follows:

- Wire, cable and electrical industries

- Building industry

- Shoe industry

- Hose industry

- Other granules

-

Notre processus de recyclage du plastique ABS

- Pour initier et récupérer le plastique ABS recyclé, nous commençons par collecter des tonnes de plastique ABS. Le recyclage des pellets en vrac s'effectue en une seule fois, réduire les dépenses commerciales et environnementales.

- La première étape consiste à bannir tous les contaminants possibles de la matière plastique ABS., qui appartiennent à la catégorie des matières plastiques non ABS. Il est nécessaire de collecter tous les déchets du plastique ABS pour le traiter davantage..

- Nous stockons le matériel traité dans des alambics ou des caisses, où nous utilisons les partenaires de transport. L'ensemble de l'installation de recyclage est réalisé avec du matériau plastique ABS..

- Chaque granulé ABS recyclé doit être adapté à l'environnement. Donc, pour répondre à l'exigence, nous préférons le contrôle de qualité et l'inspectons de près. Cela nous aide à équilibrer et à maintenir le reporting environnemental.

- Comme étape finale pour obtenir le granulé ABS recyclé, tout le matériau passe par le granulateur. Cela nous aide à créer plusieurs pastilles de plastique ABS.

Propriétés du plastique ABS disponible chez nous

Vous pouvez compter sur nous car nous fournissons le meilleur matériau plastique ABS., absorbé par de multiples propriétés:

- La composition typique du plastique ABS recyclé comprend 50 pour cent de styrène et la moitié restante est équilibrée entre le butadiène et l'acrylonitrile.

- Pour obtenir du plastique ABS plus résistant, la proportion de caoutchouc butadiène doit être augmentée.

- L'inclusion de styrène confère au plastique ABS une surface plus brillante et imperméable..

- Le plastique ABS a une résistance élevée aux chocs et la résilience provient de l'inclusion de butadiène dans celui-ci..

- Le plastique recyclé ABS est facilement soluble dans les cétones, esters, et dichlorure d'éthylène.

Pour en savoir plus sur la matière plastique ABS recyclée ou pour bénéficier de nos services, n'hésitez pas à nous contacter. Notre matériau recyclable contribuera à maintenir un environnement plus vert autour de vous.

-

Matériel LCP ou Plastique LCP, ou plastique polymère à cristaux liquides, est un type de thermoplastique connu pour ses propriétés exceptionnelles, en particulier sa température de déflexion thermique élevée, force, et résistance chimique. C’est un matériau unique qui présente une structure hautement ordonnée à la fois à l’état fondu et solide., conduisant à ses caractéristiques souhaitables.

Propriétés clés du plastique LCP:

Température de déflexion thermique élevée:

Les LCP peuvent résister à des températures élevées sans déformation significative, ce qui les rend adaptés aux applications nécessitant une résistance à la chaleur. Résistance exceptionnelle:

Ils conservent une résistance élevée même à des températures élevées, et certains LCP présentent même une résistance accrue à mesure que le matériau s'amincit. Résistance chimique:

Les LCP sont très résistants à un large éventail de produits chimiques, y compris les acides et les solvants. Ignifuge:

De nombreux LCP sont intrinsèquement ignifuges, ce qui signifie qu’ils ne s’enflamment pas ou ne brûlent pas facilement. Stabilité dimensionnelle:

Les LCP présentent une bonne stabilité dimensionnelle, ce qui signifie qu'ils conservent leur forme et leur taille même sous des contraintes ou des changements de température. Bonnes propriétés diélectriques:

Ils ont une excellente rigidité diélectrique et une faible perte diélectrique, ce qui les rend adaptés aux applications électriques et électroniques.

-