Showing 109–117 de 138 resultados

-

-

-

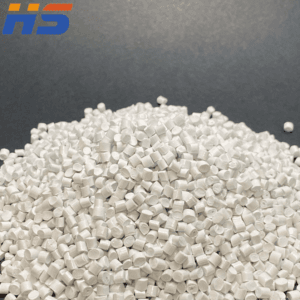

PVC Granulesis a material consisting of PVC resin, plasticizer, minerals and required additives that is produced during the mixing process by compounding machines. PVC granules have a wide range of properties and are produced in the form of soft and hard granules.

Soft PVC Plastic Granules:

The hardness range of soft granules is usually between 40 and 100 (Costa a). In order to reduce the hardness, certain amount of some kinds of plasticizers are used in the production of soft PVC granules.

A branch of soft PVC granules are TPE granules, which are combined with a substance called NBR to increase the elasticity of the granules. Soft PVC granules are widely used in wire and cable industries, automobiles, injection, shoes, doors and windows, etc.

Hard PVC Plastic Granules (UPVC):

Due to the insignificant use of plasticizers in this type of granules, they are called hard PVC or UPVC granules. The hardness range of UPVC granules is between 40 and 90 (Orilla D). These granules are usually used to produce pipe fittings, door and window profiles, ducts, shutters, etc.

PlasticKar Company, using equipped and up-to-date machines, produces and offers a variety of soft and hard PVC compounds for various applications in a wide range of industries as follows:

- Wire, cable and electrical industries

- Building industry

- Shoe industry

- Hose industry

- Other granules

-

Las propiedades de los pellets S-198al (Poliuretano termoplástico) S-198al :

- Su excelente resistencia a la abrasión, flexibilidad, y la durabilidad lo hace adecuado para plantas de zapatos

- Su capacidad para proporcionar resistencia al impacto y flexibilidad, mientras mantiene una sensación suave y gomosa, Haz que sea una opción popular para los bienes de consumo

- Su resistencia a los productos químicos, aceites, y la abrasión lo hace ideal para crear componentes industriales duraderos y confiables.

- Su flexibilidad y resistencia a los factores ambientales lo hacen adecuado para componentes electrónicos

| Propiedades físicas | Estándar de prueba | Unidad | Valor típico* |

| Densidad | ASTM D792 | g / cm3 | 1.23± 0.02 |

| Dureza de la orilla | ASTM D2240 | Costa a Orilla D | 98± 2 a |

| Resistencia a la tracción | ASTM D412 | KGF/CM2 | 350 |

| Alargamiento en el descanso | ASTM D412 | % | 400 |

| 100% Resistencia a la tracción | ASTM D412 | KGF/CM2 | 120 |

| 300% Resistencia a la tracción | ASTM D412 | KGF/CM2 | 150 |

| Fuerza de la lágrima | ASTM D624 | KGF/CM | 130 |

| Condiciones de moldeo |

| El secado | Temperatura de secado | 100° C |

| Tiempo de secado | 2-4horas |

| Tratamiento | Temperatura de procesamiento | 190-215° C |

| Procesamiento de moho | Moldura de inyección |

-

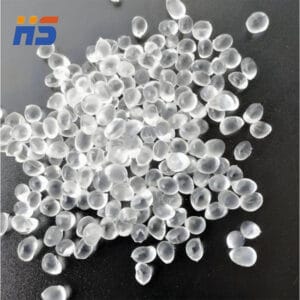

LDPE Granules

Low-Density Polyethylene pellets

Solicitud: Blown film

Melt Flow Index: 1-2

Origin: Post industrial material,

Packaging: big-bags.

Recycled LDPE (rLDPE) Pellets are made from post-consumer low-density polyethylene waste, such as plastic bags, wraps, and packaging. These eco-friendly pellets offer a sustainable alternative to virgin LDPE, providing excellent flexibility, strength, and performance for a variety of applications.

Ideal for use in packaging, film production, and consumer goods, our rLDPE pellets help businesses reduce their environmental impact while maintaining product quality. By choosing recycled LDPE, you contribute to a circular economy and promote responsible manufacturing practices.

Características clave:

- Made from 100% recycled LDPE

- Flexible, durable, and versatile for various applications

- Eco-friendly and cost-effective alternative to virgin LDPE

- Supports waste reduction and sustainable production

Choose our Recycled LDPE Pellets for a greener, more sustainable future while upholding the quality and performance of your products.

-

Gránulos de elastómero tpee :Thermoplastic polyester elastomer (TPE-E or TPEE), also known as thermoplastic Copolyester, are a class of multiblock copolymers or a physical mix of polymers (usually a plastic and a rubber) which consist of materials with both thermoplastic and elastomeric properties.

Thermoplastic elastomers show both advantages typical of rubbery and plastic materials. The principal difference between thermoset elastomers and thermoplastic elastomers is the type of crosslinking bond in their structures. In fact, crosslinking is a critical structural factor which contributes to impart high elastic properties. The crosslink in thermoset polymers is a covalent bond created during the vulcanization process.

On the other hand the crosslink in thermoplastic elastomer polymers is a weaker dipole or hydrogen bond or takes place in one of the phases of the material.

-

TPR Resin, or Goma termoplástica, es un material que combina las propiedades de caucho y plástico. Es un material versátil que se puede procesar fácilmente utilizando técnicas como moldura de inyección. TPR es conocido por su flexibilidad, durabilidad, y resistencia a los productos químicos y la meteorización

Flexibilidad y elasticidad:

TPR exhibe flexibilidad y elasticidad similares al caucho, haciéndolo adecuado para aplicaciones que requieren un material que pueda doblarse y deformarse sin romperse.

Durabilidad y fuerza:

Ofrece una buena resistencia a la tracción, resistencia a la lágrima, y resistencia a la fatiga, Permitir que resistir el estrés mecánico y el uso a largo plazo.

Resistencia química y meteorológica:

TPR es resistente a muchos productos químicos y meteorización, haciéndolo adecuado para aplicaciones al aire libre e industrial.

Procesabilidad:

Ser un termoplástico, TPR puede derretirse y remodelarse varias veces, permitiendo procesos de fabricación eficientes como moldeo y extrusión de inyección.

Reciclabalidad:

TPR se puede reciclar, convirtiéndolo en una opción más ecológica en comparación con otros materiales.

-

TPU Elastomer Pellets for many occasions

We offer an array of different grades TPU for injection parts each has its individual characteristics and can be tailored for automotive, sports, electronic products, medical, animal ID tags, toys and consumer molded products. Features sucn as short cycle time,transparent, low temperature resistance, tough UV and hydrolysis resistance, Outstanding abrasion and great weatherability performance can be achieved for applications with specific requirements.

-

TPV Resin, also known as thermoplastic vulcanizate pellets, are a type of thermoplastic elastomer known for their resistance to UV radiation, weathering, and chemicals, making them suitable for outdoor applications and harsh environments. They combine the elasticity of rubber with the processing advantages of thermoplastics, allowing for easy molding and extrusion.