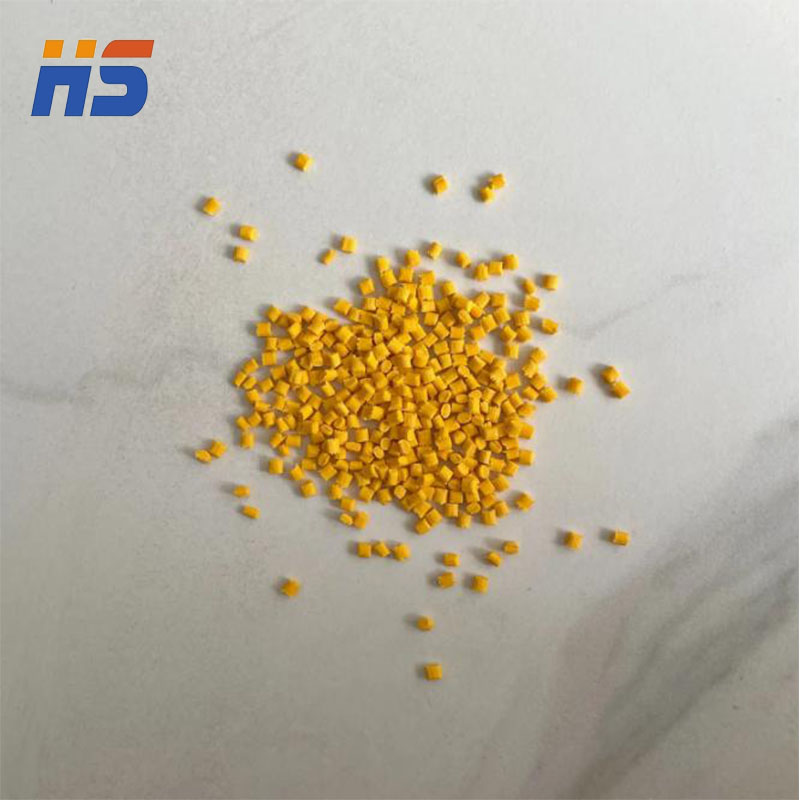

Gránulos de nylon de poliamida PA6 | Resina de ingeniería resistente a la abrasión | Grado automotriz

Gránulos de nylon de poliamida PA6

PA polyamide has excellent mechanical properties, electrical properties, wear resistance, chemical resistance, and lubricity, but it also has outstanding shortcomings, such as high water absorption, resulting in poor dimensional stability, and is also used as an engineering material. The mechanical properties still need to be further improved.

In practical applications, PA6 PA66 is the most used. The focus here is on the modification of PA6 PA66. Mainly modified from the following aspects

1 reduce the water absorption of PA to improve the dimensional stability of the product;

2 Improve the flame retardancy of PA to meet the requirements of electronics, electrical, communication and other fields;

3 Improve the mechanical mildness of the PA to achieve the strength of the metal material to meet the structural material requirements;

4 Improve the low temperature resistance of PA and enhance its ability to resist environmental stress cracking

5 Improve the wear resistance of PA to adapt to the occasions with high wear resistance;

6 Improve the antistatic property of PA to meet the requirements of mining machinery applications;

7 Improve the heat resistance of PA to adapt to the field of high temperature conditions such as automobile engines.

Por qué elegirnos

- Personal altamente profesional

- Sistemas de control de calidad

- Opciones ecológicas

Descripción

Gránulos de nylon de poliamida PA6 for textile fibers, cable sheaths, and industrial gears. Excellent wear resistance.

Aplicaciones: Fishing nets, conveyor components, and power tool housings.

Características clave: Melting point 220-225°C, glass-fiber reinforced options.

Certificaciones: Ul 94 HB, Automotive IATF 16949.

Reseñas

Todavía no hay revisiones.