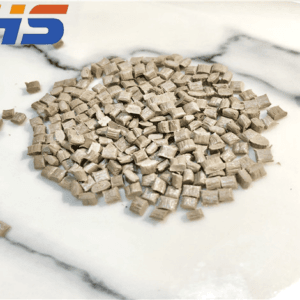

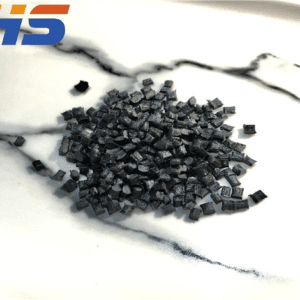

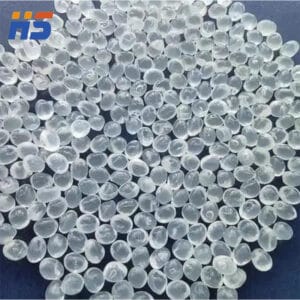

High Impact POK Resin for Industrial Gear Parts

POK Resin has high toughness, sufficient tensile strength and flexural modulus, and balanced performance

Compared with Nylon, PBT has 230% higher impact strength. It also has excellent hydrolysis resistance. It maintains high tensile strength and impact strength under wet conditions, and has high elongation.

PK high heat deformation temperature: HDT is 200℃, can be used for a long time in high temperature environment

PK has excellent chemical resistance: chemical resistance is second only to PPS. Water and water vapor stability

PK has high barrier properties: hydrocarbons. Passed the permeability test of unleaded gasoline @93℃*15 days, better than Teflon, and the gas barrier is equivalent to EVOH

PK has good friction performance: its wear resistance is 14 times that of POM and it has excellent low noise

PK has high production efficiency, and high crystallinity polyketone helps to shorten the molding cycle

PK Main Applications

Widely used in machinery, instruments, auto parts, electrical and electronic equipment, railways, home appliances, communications, textile machinery, sports and leisure products, oil pipelines, fuel tanks and some precision engineering products.