Showing 64–72 de 174 resultados

-

HDPE (Polietileno de alta densidad) Descripción del Producto

Alta resistencia · liviano & Duradero · ecológico

HDPE (Polietileno de alta densidad) es un plástico de alto rendimiento conocido por su excelente resistencia al impacto, Resistencia a la corrosión química, y propiedades livianas. Su estructura densa asegura una durabilidad superior y permanece fácil de manejar.

Características clave:

✅ Alta fuerza & Resistencia al desgaste - Resiste los impactos y la deformación, Adecuado para condiciones difíciles.

✅ Químico & Resistente a la humedad - resistir ácidos, alcalino, aceites, y humedad, Ideal para uso interior/exterior.

✅ No tóxico & Reciclable - cumple con los estándares de seguridad y apoya las prácticas sostenibles.

✅ Fácil de limpiar - La superficie lisa previene la acumulación de suciedad.

Aplicaciones:

Embalaje industrial, productos domésticos, contenedores logísticos, equipo al aire libre, y más.

Elija HDPE para un confiable, solución duradera!

(Se puede personalizar con detalles específicos como dimensiones, bandera, o características especiales.)

-

HDPE (Polietileno de alta densidad) Descripción del Producto

Alta resistencia · liviano & Duradero · ecológico

HDPE (Polietileno de alta densidad) es un plástico de alto rendimiento conocido por su excelente resistencia al impacto, Resistencia a la corrosión química, y propiedades livianas. Su estructura densa asegura una durabilidad superior y permanece fácil de manejar.

Características clave:

✅ Alta fuerza & Resistencia al desgaste - Resiste los impactos y la deformación, Adecuado para condiciones difíciles.

✅ Químico & Resistente a la humedad - resistir ácidos, alcalino, aceites, y humedad, Ideal para uso interior/exterior.

✅ No tóxico & Reciclable - cumple con los estándares de seguridad y apoya las prácticas sostenibles.

✅ Fácil de limpiar - La superficie lisa previene la acumulación de suciedad.

Aplicaciones:

Embalaje industrial, productos domésticos, contenedores logísticos, equipo al aire libre, y más.

Elija HDPE para un confiable, solución duradera!

(Se puede personalizar con detalles específicos como dimensiones, bandera, o características especiales.)

-

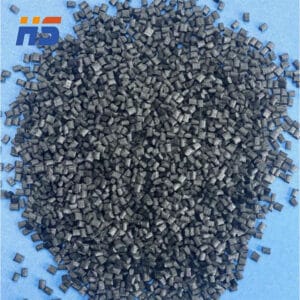

PPS Granules Polyphenylene sulfide, commonly referred to as PPS, is a semi-crystalline thermoplastic with a polymeric structure that gives it a remarkable degree of chemical resistance. In fact, there are no known solvents for this high-performance thermoplastic below 392°F (200° C). Its other notable attributes are its inherent flame resistance, electrical properties and its high mechanical strength. Most commercial grades of PPS achieve a UL 94 V-0 flammability rating without flame-retardant additives.

While the unmodified PPS polymer exhibits good all-around performance, the addition of fiber-reinforcement significantly boosts its toughness, structural and thermal properties. A two-fold increase in heat deflection temperature and more than triple the flexural modulus are the main reasons for the far greater usage of 40% glass fiber-reinforced PPS over unfilled grades for load bearing molded and machined parts exposed to higher thermal conditions.

-

TPEE Resin also Thermoplastic polyester elastomer (TPE-E or TPEE), also known as thermoplastic Copolyester, are a class of multiblock copolymers or a physical mix of polymers (usually a plastic and a rubber) which consist of materials with both thermoplastic and elastomeric properties.

Thermoplastic elastomers show both advantages typical of rubbery and plastic materials. The principal difference between thermoset elastomers and thermoplastic elastomers is the type of crosslinking bond in their structures. In fact, crosslinking is a critical structural factor which contributes to impart high elastic properties. The crosslink in thermoset polymers is a covalent bond created during the vulcanization process.

On the other hand the crosslink in thermoplastic elastomer polymers is a weaker dipole or hydrogen bond or takes place in one of the phases of the material.

-

Resistant TPV pellets, also known as thermoplastic vulcanizate pellets, are a type of thermoplastic elastomer known for their resistance to UV radiation, weathering, and chemicals, making them suitable for outdoor applications and harsh environments. They combine the elasticity of rubber with the processing advantages of thermoplastics, allowing for easy molding and extrusion.

-

Recycled PA66 Granules

.

1. Reinforced PA66 Material

2. Used for Injection Molding

3. High mechanical strength

4. FREE SAMPLE

Recycled PA66 Plastic Pellets

Product Details

Recycled PA66 Nylon Pellets

Why choose PA66 over PA6?

Slightly better short term thermal resistance

Absorbs slightly less moisture

Higher modulus

Better wear resistance

Better short term heat resistance

is one of the professional recycled pa66 plastic pellets manufacturers, you can order high quality recycled pa66 plastic pellets at good price from our factory.

-

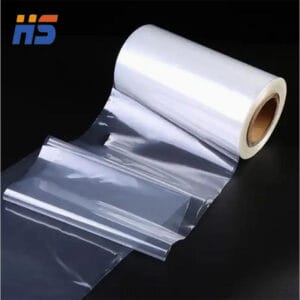

Clarity Plastic Film is a necessity for contractors, DIYers that are remodeling their home, or anyone needing a tough y durable plastic sheeting for a project. Shop our extensive selection and get the best prices and fast shipping.

-

TPEE Pellets :Thermoplastic polyester elastomer (TPE-E or TPEE), also known as thermoplastic Copolyester, are a class of multiblock copolymers or a physical mix of polymers (usually a plastic and a rubber) which consist of materials with both thermoplastic and elastomeric properties.

Thermoplastic elastomers show both advantages typical of rubbery and plastic materials. The principal difference between thermoset elastomers and thermoplastic elastomers is the type of crosslinking bond in their structures. In fact, crosslinking is a critical structural factor which contributes to impart high elastic properties. The crosslink in thermoset polymers is a covalent bond created during the vulcanization process.

On the other hand the crosslink in thermoplastic elastomer polymers is a weaker dipole or hydrogen bond or takes place in one of the phases of the material.

-

PPO Pellets Polyphenylene Oxide (PPO) is a lightweight resin that’s commonly used and mixed with other resins to facilitate manufacturing processes. It resists heat very well, and as a result, can’t easily be melted down and used in different injection molds or recycled for other uses.