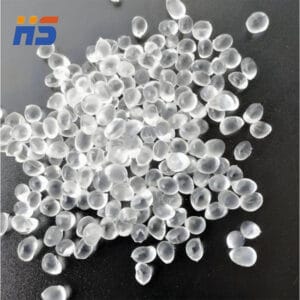

TPR Material for Flexible Over-Molding Applications

TPR Material, o Goma termoplástica, es un material que combina las propiedades de caucho y plástico. Es un material versátil que se puede procesar fácilmente utilizando técnicas como moldura de inyección. TPR es conocido por su flexibilidad, durabilidad, y resistencia a los productos químicos y la meteorización

- Flexibilidad y elasticidad:TPR exhibe flexibilidad y elasticidad similares al caucho, haciéndolo adecuado para aplicaciones que requieren un material que pueda doblarse y deformarse sin romperse.

- Durabilidad y fuerza:Ofrece una buena resistencia a la tracción, resistencia a la lágrima, y resistencia a la fatiga, Permitir que resistir el estrés mecánico y el uso a largo plazo.

- Resistencia química y meteorológica:TPR es resistente a muchos productos químicos y meteorización, haciéndolo adecuado para aplicaciones al aire libre e industrial.

- Procesabilidad:Ser un termoplástico, TPR puede derretirse y remodelarse varias veces, permitiendo procesos de fabricación eficientes como moldeo y extrusión de inyección.

- Reciclabalidad:TPR se puede reciclar, convirtiéndolo en una opción más ecológica en comparación con otros materiales.