Showing 136–144 de 174 resultados

-

-

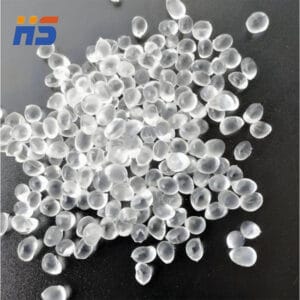

PVC Granulesis a material consisting of PVC resin, plastificante, minerales y aditivos requeridos que se producen durante el proceso de mezcla mediante máquinas mezcladoras. Los gránulos de PVC tienen una amplia gama de propiedades y se producen en forma de gránulos blandos y duros..

Gránulos de plástico de PVC blando:

El rango de dureza de los gránulos blandos suele estar entre 40 y 100 (Costa a). Para reducir la dureza, Se utiliza cierta cantidad de algunos tipos de plastificantes en la producción de gránulos de PVC blando..

Una rama de los gránulos de PVC blando son los gránulos de TPE., que se combinan con una sustancia llamada NBR para aumentar la elasticidad de los gránulos. Los gránulos de PVC blando se utilizan ampliamente en las industrias de alambres y cables., automóviles, inyección, zapatos, puertas y ventanas, etc..

Gránulos de plástico de PVC duro (PVC):

Debido al uso insignificante de plastificantes en este tipo de gránulos, se llaman gránulos de PVC duro o UPVC. El rango de dureza de los gránulos de UPVC está entre 40 y 90 (Orilla D). Estos gránulos se utilizan generalmente para producir accesorios para tuberías., perfiles de puertas y ventanas, conductos, contraventanas, etc..

PlasticKar empresa, utilizando máquinas equipadas y modernas, produce y ofrece una variedad de compuestos de PVC blandos y duros para diversas aplicaciones en una amplia gama de industrias de la siguiente manera:

- Cable, cables y electricos industrias

- Bindustria de la construcción

- Industria del calzado

- industria de mangueras

- Otro gránulos

-

Las propiedades de los pellets S-198al (Poliuretano termoplástico) S-198al :

- Su excelente resistencia a la abrasión, flexibilidad, y la durabilidad lo hace adecuado para plantas de zapatos

- Su capacidad para proporcionar resistencia al impacto y flexibilidad, mientras mantiene una sensación suave y gomosa, Haz que sea una opción popular para los bienes de consumo

- Su resistencia a los productos químicos, aceites, y la abrasión lo hace ideal para crear componentes industriales duraderos y confiables.

- Su flexibilidad y resistencia a los factores ambientales lo hacen adecuado para componentes electrónicos

| Propiedades físicas | Estándar de prueba | Unidad | Valor típico* |

| Densidad | ASTM D792 | g / cm3 | 1.23± 0.02 |

| Dureza de la orilla | ASTM D2240 | Costa a Orilla D | 98± 2 a |

| Resistencia a la tracción | ASTM D412 | KGF/CM2 | 350 |

| Alargamiento en el descanso | ASTM D412 | % | 400 |

| 100% Resistencia a la tracción | ASTM D412 | KGF/CM2 | 120 |

| 300% Resistencia a la tracción | ASTM D412 | KGF/CM2 | 150 |

| Fuerza de la lágrima | ASTM D624 | KGF/CM | 130 |

| Condiciones de moldeo |

| El secado | Temperatura de secado | 100° C |

| Tiempo de secado | 2-4horas |

| Tratamiento | Temperatura de procesamiento | 190-215° C |

| Procesamiento de moho | Moldura de inyección |

-

POE Elastomer derived from Polyolefin Elastomer, Son gránulos de plástico versátiles que se utilizan en diversas industrias debido a su flexibilidad., resistencia a la intemperie, y resistencia al impacto. Se utilizan principalmente para PP endurecido, Orina, y PA en la industria del automóvil, para aislamiento y revestimiento de alambres y cables, y también para productos industriales como mangueras y cintas transportadoras.. Además, encuentran aplicaciones en dispositivos médicos, electrodomésticos, artículos deportivos, y películas de embalaje.

-

LDPE Granules

Pellets de polietileno de baja densidad

Solicitud: película soplada

Índice de flujo de fusión: 1-2

Origen: Material postindustrial,

Embalaje: bolsas grandes.

PEBD reciclado (LDPE) Pellets están fabricados a partir de residuos de polietileno de baja densidad posconsumo, como bolsas de plástico, envolturas, y embalaje. Estos pellets ecológicos ofrecen una alternativa sostenible al LDPE virgen, proporcionando una excelente flexibilidad, fortaleza, y rendimiento para una variedad de aplicaciones.

Ideal para uso en embalaje., producción cinematográfica, y bienes de consumo, Nuestros gránulos de rLDPE ayudan a las empresas a reducir su impacto ambiental manteniendo la calidad del producto.. Eligiendo LDPE reciclado, Contribuyes a una economía circular y promueves prácticas de fabricación responsables..

Características clave:

- hecho de 100% PEBD reciclado

- Flexible, durable, y versátil para diversas aplicaciones

- Alternativa ecológica y rentable al LDPE virgen

- Apoya la reducción de residuos y la producción sostenible

Elige nuestro Pellets de LDPE reciclados por un más verde, un futuro más sostenible manteniendo al mismo tiempo la calidad y el rendimiento de sus productos.

-

TPR Pellets o Goma termoplástica, es un material que combina las propiedades de caucho y plástico. Es un material versátil que se puede procesar fácilmente utilizando técnicas como moldura de inyección. TPR es conocido por su flexibilidad, durabilidad, y resistencia a los productos químicos y la meteorización

Flexibilidad y elasticidad:

TPR exhibe flexibilidad y elasticidad similares al caucho, haciéndolo adecuado para aplicaciones que requieren un material que pueda doblarse y deformarse sin romperse.

Durabilidad y fuerza:

Ofrece una buena resistencia a la tracción, resistencia a la lágrima, y resistencia a la fatiga, Permitir que resistir el estrés mecánico y el uso a largo plazo.

Resistencia química y meteorológica:

TPR es resistente a muchos productos químicos y meteorización, haciéndolo adecuado para aplicaciones al aire libre e industrial.

Procesabilidad:

Ser un termoplástico, TPR puede derretirse y remodelarse varias veces, permitiendo procesos de fabricación eficientes como moldeo y extrusión de inyección.

Reciclabalidad:

TPR se puede reciclar, convirtiéndolo en una opción más ecológica en comparación con otros materiales.

-

Goma termoplástica, es un material que combina las propiedades de caucho y plástico. Es un material versátil que se puede procesar fácilmente utilizando técnicas como moldura de inyección. TPR es conocido por su flexibilidad, durabilidad, y resistencia a los productos químicos y la meteorización

Flexibilidad y elasticidad:

TPR exhibe flexibilidad y elasticidad similares al caucho, haciéndolo adecuado para aplicaciones que requieren un material que pueda doblarse y deformarse sin romperse.

Durabilidad y fuerza:

Ofrece una buena resistencia a la tracción, resistencia a la lágrima, y resistencia a la fatiga, Permitir que resistir el estrés mecánico y el uso a largo plazo.

Resistencia química y meteorológica:

TPR es resistente a muchos productos químicos y meteorización, haciéndolo adecuado para aplicaciones al aire libre e industrial.

Procesabilidad:

Ser un termoplástico, TPR puede derretirse y remodelarse varias veces, permitiendo procesos de fabricación eficientes como moldeo y extrusión de inyección.

Reciclabalidad:

TPR se puede reciclar, convirtiéndolo en una opción más ecológica en comparación con otros materiales.

-

Gránulos de elastómero tpee :Thermoplastic polyester elastomer (TPE-E or TPEE), also known as thermoplastic Copolyester, are a class of multiblock copolymers or a physical mix of polymers (usually a plastic and a rubber) which consist of materials with both thermoplastic and elastomeric properties.

Thermoplastic elastomers show both advantages typical of rubbery and plastic materials. The principal difference between thermoset elastomers and thermoplastic elastomers is the type of crosslinking bond in their structures. In fact, crosslinking is a critical structural factor which contributes to impart high elastic properties. The crosslink in thermoset polymers is a covalent bond created during the vulcanization process.

On the other hand the crosslink in thermoplastic elastomer polymers is a weaker dipole or hydrogen bond or takes place in one of the phases of the material.

-

TPEE Material :Thermoplastic polyester elastomer (TPE-E or TPEE), also known as thermoplastic Copolyester, are a class of multiblock copolymers or a physical mix of polymers (usually a plastic and a rubber) which consist of materials with both thermoplastic and elastomeric properties.

Thermoplastic elastomers show both advantages typical of rubbery and plastic materials. The principal difference between thermoset elastomers and thermoplastic elastomers is the type of crosslinking bond in their structures. In fact, crosslinking is a critical structural factor which contributes to impart high elastic properties. The crosslink in thermoset polymers is a covalent bond created during the vulcanization process.

On the other hand the crosslink in thermoplastic elastomer polymers is a weaker dipole or hydrogen bond or takes place in one of the phases of the material.