Showing 64–72 of 174 Ergebnisse

-

HDPE (High-Density Polyethylene) Product Description

High Strength · Lightweight & Durable · Eco-Friendly

HDPE (High-Density Polyethylene) is a high-performance plastic known for its excellent impact resistance, chemical corrosion resistance, and lightweight properties. Its dense structure ensures superior durability while remaining easy to handle.

Hauptmerkmale:

✅ High Strength & Wear Resistance – Resists impacts and deformation, suitable for tough conditions.

✅ Chemical & Moisture Resistant – Withstands acids, alkalis, oils, and humidity, ideal for indoor/outdoor use.

✅ Non-Toxic & Recyclable – Meets safety standards and supports sustainable practices.

✅ Easy to Clean – Smooth surface prevents dirt buildup.

Anwendungen:

Industrial packaging, household products, logistics containers, outdoor equipment, and more.

Choose HDPE for a reliable, long-lasting solution!

(Can be customized with specific details like dimensions, colors, or special features.)

-

HDPE (High-Density Polyethylene) Product Description

High Strength · Lightweight & Durable · Eco-Friendly

HDPE (High-Density Polyethylene) is a high-performance plastic known for its excellent impact resistance, chemical corrosion resistance, and lightweight properties. Its dense structure ensures superior durability while remaining easy to handle.

Hauptmerkmale:

✅ High Strength & Wear Resistance – Resists impacts and deformation, suitable for tough conditions.

✅ Chemical & Moisture Resistant – Withstands acids, alkalis, oils, and humidity, ideal for indoor/outdoor use.

✅ Non-Toxic & Recyclable – Meets safety standards and supports sustainable practices.

✅ Easy to Clean – Smooth surface prevents dirt buildup.

Anwendungen:

Industrial packaging, household products, logistics containers, outdoor equipment, and more.

Choose HDPE for a reliable, long-lasting solution!

(Can be customized with specific details like dimensions, colors, or special features.)

-

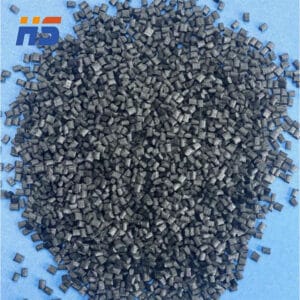

PPS-Granulat Polyphenylensulfid, allgemein als PPS bezeichnet, ist ein teilkristalliner Thermoplast mit einer Polymerstruktur, die ihm eine bemerkenswerte chemische Beständigkeit verleiht. Tatsächlich, Unter 392 °F sind für diesen Hochleistungsthermoplast keine Lösungsmittel bekannt (200°C). Seine weiteren bemerkenswerten Eigenschaften sind seine inhärente Flammwidrigkeit, elektrische Eigenschaften und seine hohe mechanische Festigkeit. Die meisten kommerziellen PPS-Typen erreichen einen UL 94 V-0 Brennbarkeitsklasse ohne flammhemmende Zusätze.

Während das unmodifizierte PPS-Polymer eine gute Gesamtleistung aufweist, Durch den Zusatz von Faserverstärkungen wird die Zähigkeit deutlich erhöht, strukturelle und thermische Eigenschaften. Eine Verdoppelung der Wärmeformbeständigkeit und mehr als das Dreifache des Biegemoduls sind die Hauptgründe für den weitaus höheren Einsatz von 40% glasfaserverstärktes PPS gegenüber ungefüllten Typen für tragende Form- und Bearbeitungsteile, die höheren thermischen Bedingungen ausgesetzt sind.

-

TPEE Resin also Thermoplastic polyester elastomer (TPE-E oder TPEE), auch bekannt als thermoplastisches Copolyester, sind eine Klasse von Multiblockcopolymeren oder eine physikalische Mischung von Polymeren (normalerweise ein Kunststoff und ein Gummi) die aus Materialien mit sowohl thermoplastischen als auch elastischen Eigenschaften bestehen.

Thermoplastische Elastomere weisen beide Vorteile auf, die für gummiartige und plastische Materialien typisch sind. Der Hauptunterschied zwischen duroplastischen Elastomeren und thermoplastischen Elastomeren besteht in der Art der Vernetzungsbindung in ihren Strukturen. Tatsächlich, Vernetzung ist ein entscheidender Strukturfaktor, der dazu beiträgt, hohe elastische Eigenschaften zu verleihen. Die Vernetzung in duroplastischen Polymeren ist eine kovalente Bindung, die während des Vulkanisationsprozesses entsteht.

Andererseits ist die Vernetzung in thermoplastischen Elastomerpolymeren eine schwächere Dipol- oder Wasserstoffbindung oder findet in einer der Phasen des Materials statt.

-

Resistant TPV pellets, auch bekannt als thermoplastische Vulkanisatpellets, Sind eine Art thermoplastisches Elastomer, das für seine Beständigkeit gegen UV-Strahlung bekannt ist, Verwitterung, und Chemikalien, Dadurch sind sie für Außenanwendungen und raue Umgebungen geeignet. Sie vereinen die Elastizität von Gummi mit den Verarbeitungsvorteilen von Thermoplasten, Ermöglicht einfaches Formen und Extrudieren.

-

Recycled PA66 Granules

.

1. Reinforced PA66 Material

2. Used for Injection Molding

3. High mechanical strength

4. FREE SAMPLE

Recycled PA66 Plastic Pellets

Product Details

Recycled PA66 Nylon Pellets

Why choose PA66 over PA6?

Slightly better short term thermal resistance

Absorbs slightly less moisture

Higher modulus

Better wear resistance

Better short term heat resistance

is one of the professional recycled pa66 plastic pellets manufacturers, you can order high quality recycled pa66 plastic pellets at good price from our factory.

-

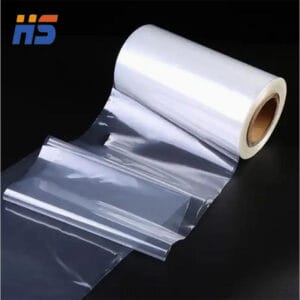

Clarity Plastic Film is a necessity for contractors, DIYers that are remodeling their home, or anyone needing a tough Und dauerhaft plastic sheeting for a project. Shop our extensive selection and get the best prices and fast shipping.

-

TPEE Pellets :Thermoplastisches Polyester-Elastomer (TPE-E oder TPEE), auch bekannt als thermoplastisches Copolyester, sind eine Klasse von Multiblockcopolymeren oder eine physikalische Mischung von Polymeren (normalerweise ein Kunststoff und ein Gummi) die aus Materialien mit sowohl thermoplastischen als auch elastischen Eigenschaften bestehen.

Thermoplastische Elastomere weisen beide Vorteile auf, die für gummiartige und plastische Materialien typisch sind. Der Hauptunterschied zwischen duroplastischen Elastomeren und thermoplastischen Elastomeren besteht in der Art der Vernetzungsbindung in ihren Strukturen. Tatsächlich, Vernetzung ist ein entscheidender Strukturfaktor, der dazu beiträgt, hohe elastische Eigenschaften zu verleihen. Die Vernetzung in duroplastischen Polymeren ist eine kovalente Bindung, die während des Vulkanisationsprozesses entsteht.

Andererseits ist die Vernetzung in thermoplastischen Elastomerpolymeren eine schwächere Dipol- oder Wasserstoffbindung oder findet in einer der Phasen des Materials statt.

-

PPO Pellets Polyphenylene Oxide (PPO) is a lightweight resin that’s commonly used and mixed with other resins to facilitate manufacturing processes. It resists heat very well, and as a result, can’t easily be melted down and used in different injection molds or recycled for other uses.